Dye Penetrant Testing (DPI) is a non-destructive testing method used to detect surface-breaking defects in non-porous materials such as metals, plastics, ceramics, and composites.

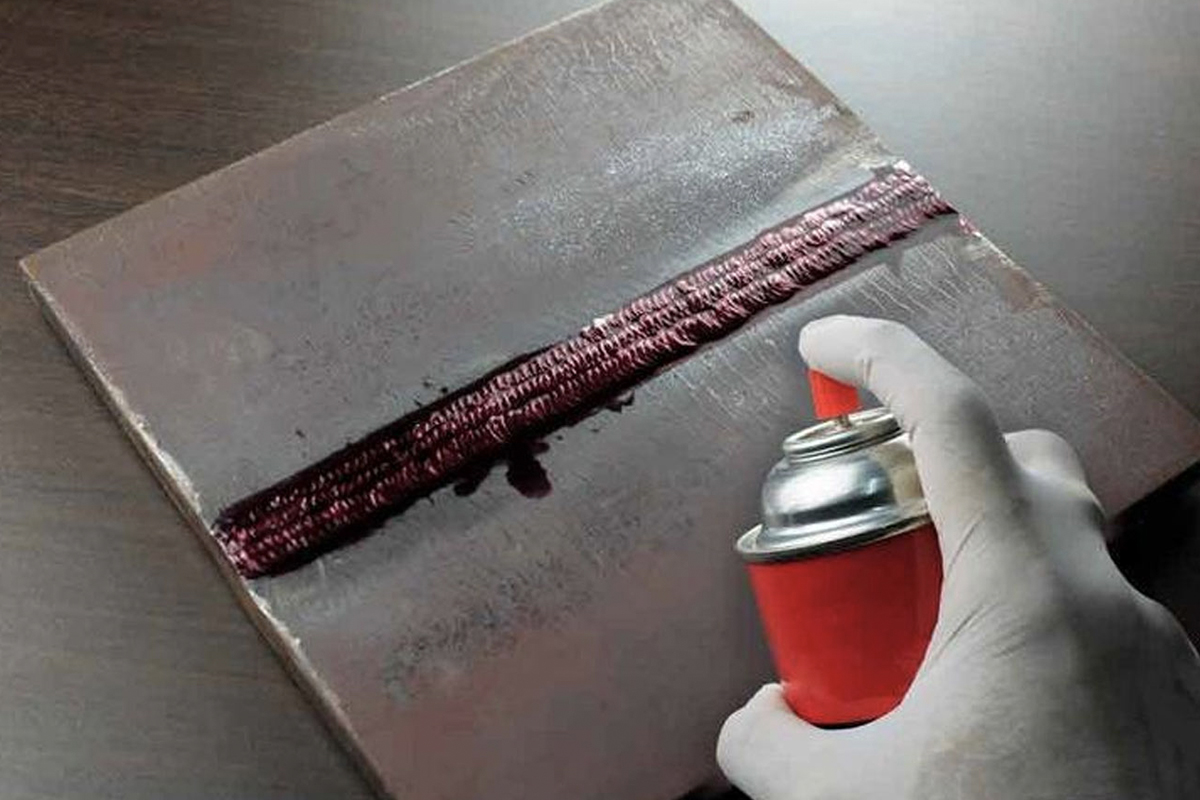

The process involves applying a liquid dye penetrant to the surface of the material being tested. The dye is typically a bright-colored liquid that is highly visible against the background of the material. The dye penetrates into any surface cracks, voids, or other defects by capillary action.

After allowing sufficient time for the dye to penetrate into any defects, excess dye is removed from the surface of the material. A developer is then applied, which draws the trapped dye out of the defects to the surface, making them easily visible under white light or UV light.

The inspector can then visually inspect the surface for indications of defects, such as cracks, pores, laps, seams, or other discontinuities. The size and shape of the indications can provide valuable information about the nature and severity of the defects present.

DPI is a widely used testing method due to its simplicity, cost-effectiveness, and ability to detect surface defects that may not be visible to the naked eye. It is commonly used in industries such as aerospace, automotive, manufacturing, and construction to ensure the quality and integrity of materials and components.